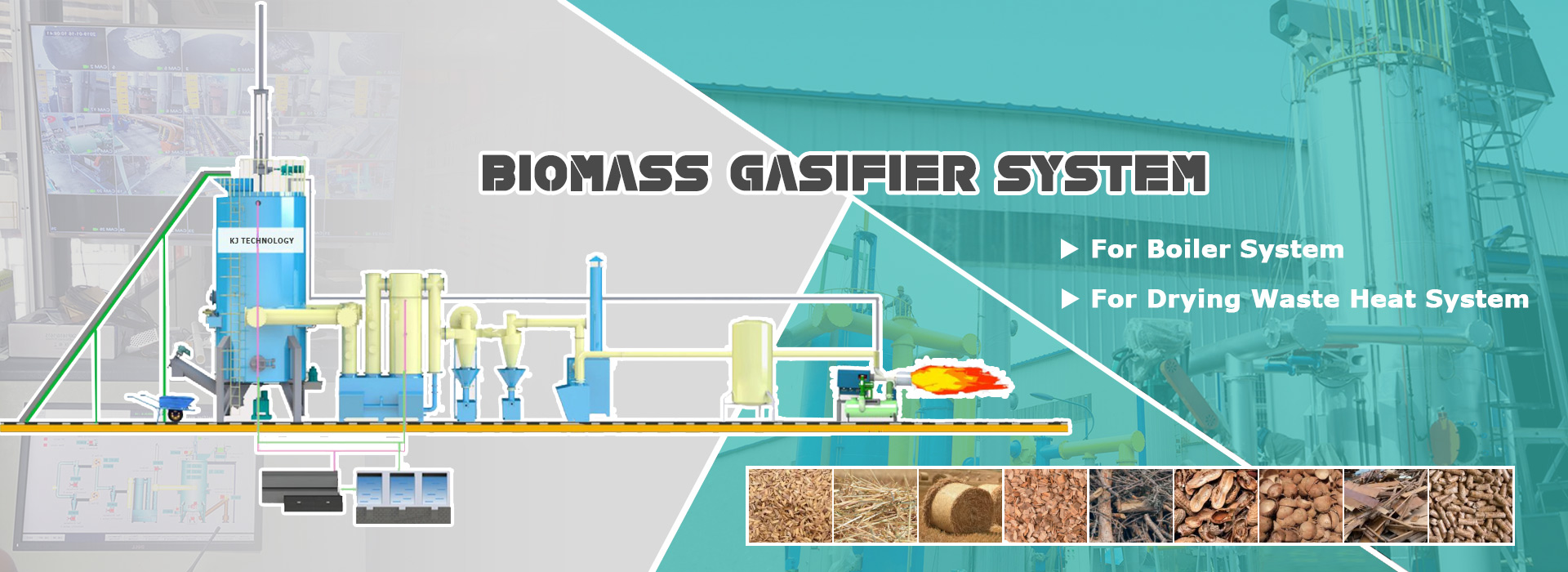

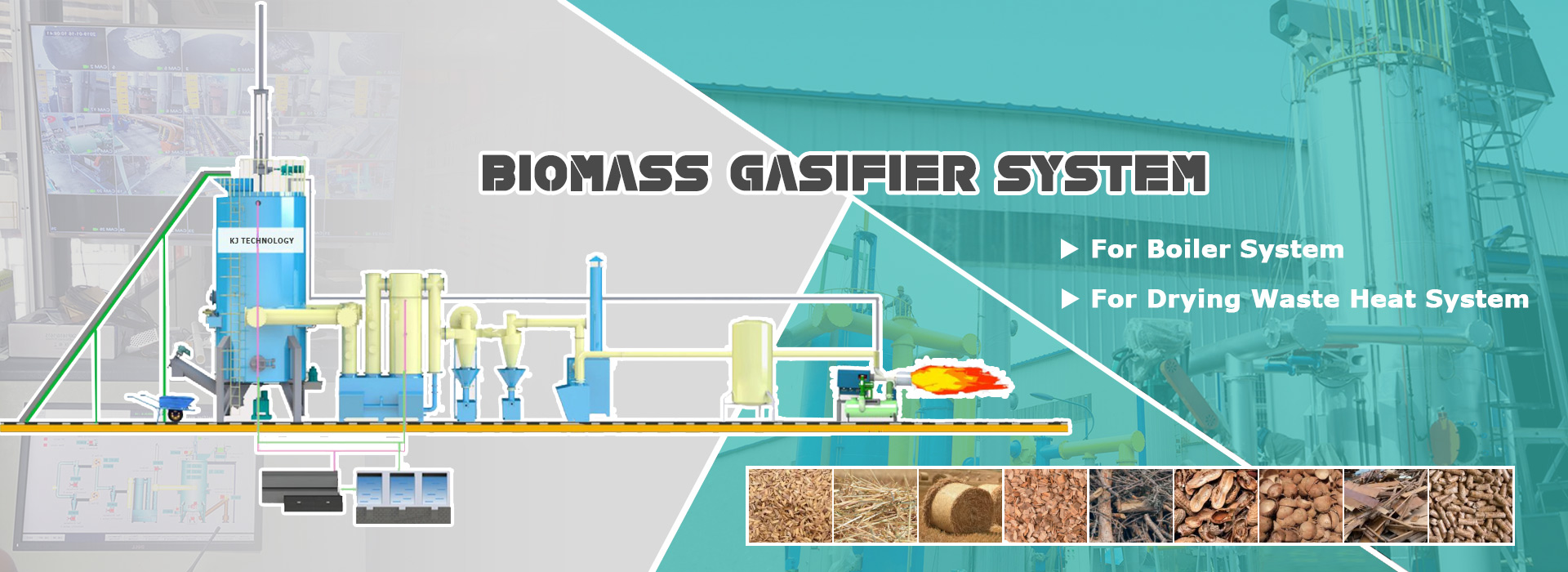

Biomass gasifierpoOkjpyrolysis

The carbon dioxide released by the burning of biomass fuels is absorbed by plants during growth and does not increase the total amount of carbon dioxide in the atmosphere. Internationally, it is known as zero CO2 emissions, that is, carbon neutral.poOkjpyrolysis

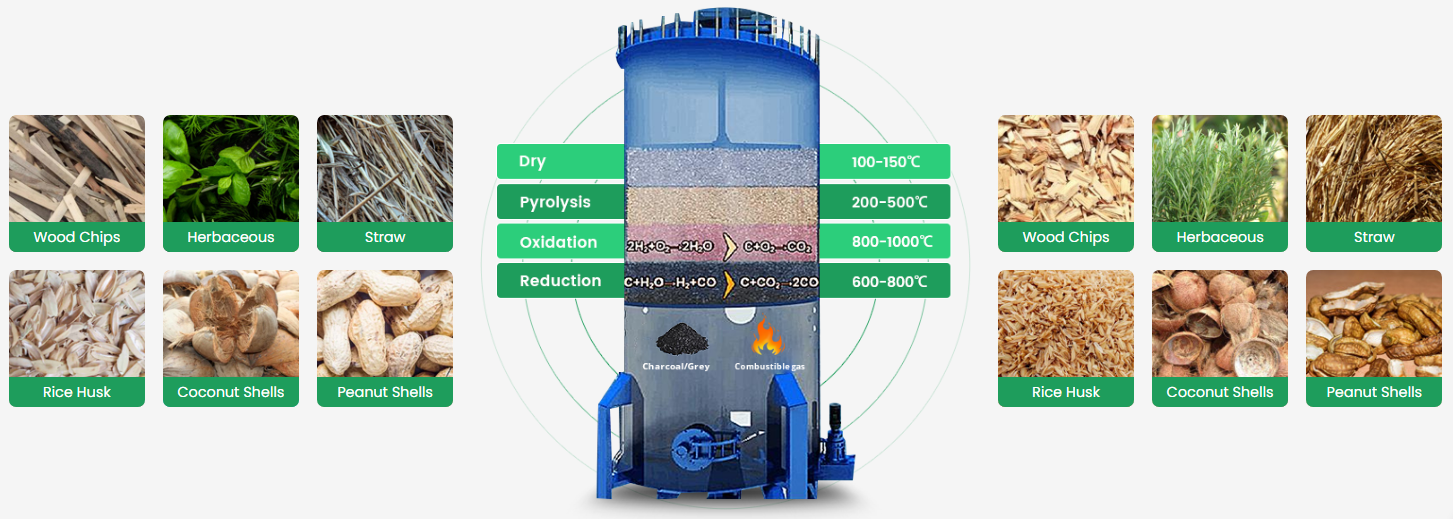

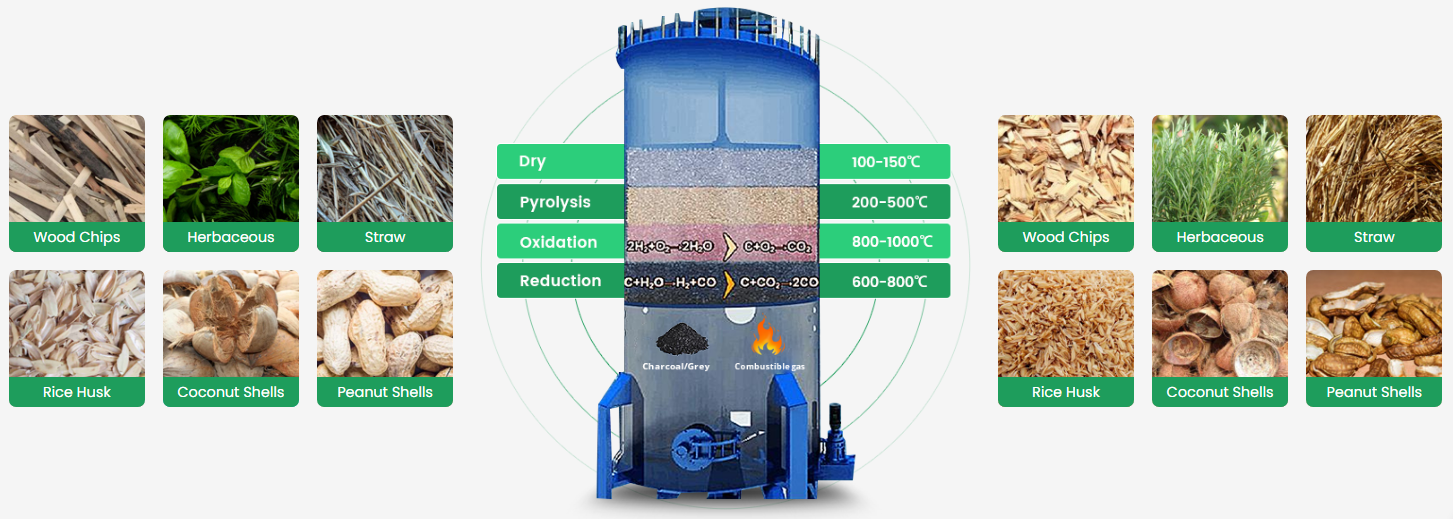

poOkjpyrolysispoOkjpyrolysispoOkjpyrolysisBiomass gasification reaction principlepoOkjpyrolysis

poOkjpyrolysispoOkjpyrolysispoOkjpyrolysisBiomass gasification reaction principlepoOkjpyrolysis

poOkjpyrolysis

poOkjpyrolysis Biomass gasification is a thermochemical process that converts biomass fuel into combustible gas. During this process, water vapor, free oxygen or combined oxygen react thermochemically with the carbon in the fuel to produce flammable gas, black carbon, wood vinegar, wood tar, etc.poOkjpyrolysis

poOkjpyrolysis

Simply put, the gasification process reacts simultaneously in different parts of the gasifier at the same time. The four layers are the drying layer, the cracking layer, the oxidizing layer, and the reducing layer.poOkjpyrolysis

poOkjpyrolysis

Dry layer: Biomass raw materials usually contain 5-35% moisture, and some raw materials contain more than 50% moisture. In the drying layer of the gasifier, after the temperature exceeds 100 degrees, the moisture in the biomass feedstock is converted into steam . But in the dry layer, the biomass feedstock itself does not decompose.poOkjpyrolysis

poOkjpyrolysis

Cracking layer: The principle of cracking is the thermal decomposition process in which biomass is heated in the absence of oxygen. There are three products of pyrolysis, solid, liquid (tar) and gas. The ratio of these three products varies according to the composition and operating conditions of each biomass feedstock. Gas is also produced during pyrolysis, but the calorific value of the gas is usually 3.5-8.9MJ/M3. According to the experience of our company Wuxi Teneng Electromechanical Co., Ltd., no matter how the biomass gasifier is designed, the cracking layer is always carried out in the low temperature area and produces condensable hydrocarbons.poOkjpyrolysis

poOkjpyrolysis

Oxide layer: We usually add air (ie oxygen) and water vapor to the oxide layer, and the nitrogen in the air does not react with the raw materials here. The temperature of the oxide layer is usually 700-2000 degrees Celsius. In the oxide layer, the carbon in the biomass feedstock reacts with oxygen in a complex phase. The role of the oxide layer is to provide heat and CO2 and H20 to the gasification layer.poOkjpyrolysis

Source of raw materials:poOkjpyrolysis

Biomass gasifier system equipment independently designed, developed and manufactured by KJ TECHNOLOGY. The raw material sources are widely applicable to biomass, branches, rice husks, straw, nut shells, coconut shells, palm shells, sawdust, building templates, furniture factory waste, etc.poOkjpyrolysis

poOkjpyrolysis

Main types of biomass gasificationpoOkjpyrolysis

The type of biomass gasification used by KJ TECHNOLOGY is fixed bed suction type. The advantages of this system are stable and reliable gas production operation and strong continuous workability. It is commonly used in industry. The gasification temperature generated by this system is between 750°C and 850°C. The flammable mixed gases generated are CO, CH4, H2, and the non-flammable gas is N2. The gasification efficiency is 75%, and about 3-5% biochar can be produced. If there are special requirements, the biochar production ratio can be increased again.poOkjpyrolysis