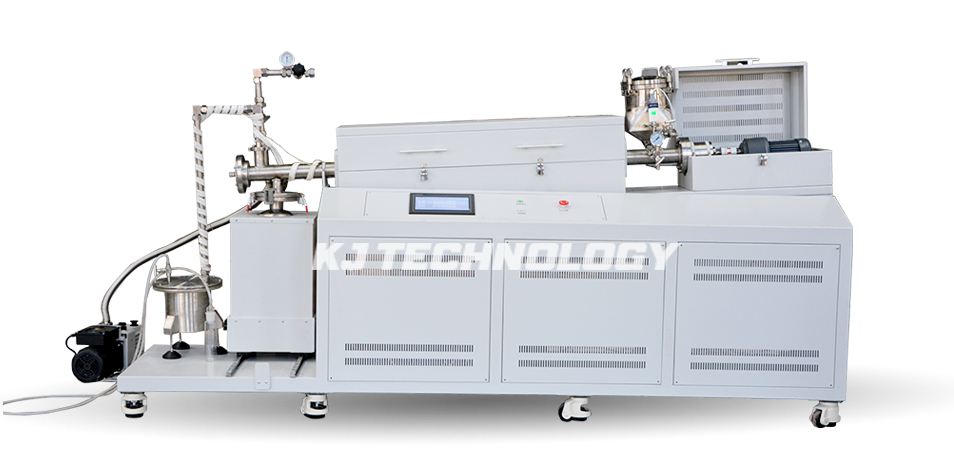

Elastomeric Material Pyrolysis Equipment

KJ-1200T

KJ-1200T Working temperature:

≤1000℃

Working temperature:

≤1000℃

Temperature Zone:

300*400*300 mm 3 hot zones

Temperature Zone:

300*400*300 mm 3 hot zones

Application:

Specially designed for sintering of inorganic compound, such as, mineral particles and battery material and with better uniformity.

Application:

Specially designed for sintering of inorganic compound, such as, mineral particles and battery material and with better uniformity.

Introduction

Lab Scale Elastomeric Material Pyrolysis Furnace with Hopper and Impingers is a high temperature reactor with special rotary and tilt function. It is specially designed for sintering of inorganic compound, such as, mineral particles and battery material and with better uniformity. Multi heating zone, condenser and tail gas collect equipment can be optional part according to different experiment.

| Technical Parameter | |||

| Model | KJ-1200T | ||

| Display | LCD Touch Screen It can storage temp. Time, pressure value and support to output values with USB disk. |

||

| Working Temperature | ≤1000℃ | ||

| Heating Rate | Suggestion 0~10℃/min | ||

| Temperature Zone | 300+400+300 mm 3 hot zones |

||

| Temp. Control Thermocouple | 3pcs* K type thermocouple for each zone outside furnace tube | ||

| Monitoring thermocouple | 1 piece K type in the middle of hot zone inside furnace tube and the temp. will read and display on the LCD touch screen of furnace. But this thermocouple is for monitoring temp. Only, can’t control temp. | ||

| Temperature Control Accuracy | ±1℃ | ||

| Tube Diameter | Ф70mm OD | ||

| Tube Material | Stainless Steel Tube | ||

| Tube sealing | The two ends of tube is with flange sealing. And there is gas inlet/outlet on the flange. One side of tube is with feeder (apprx. 6L) |

||

| The other side is with container (silo) | |||

| Max. Vacuum Level | 20mbar | ||

| Vacuum Pump | 4L/S rotary vane vacuum pump | ||

| Digital Vacuum Gauge | measuring range is: 3.8*10-5 to 1125 torr | ||

| Mass Flow Meter | Flow range: to 1.6SLM for N2 LCD Touch Screen |

||

| Heating Element | Resistance wire with Mo | ||

| Tube Rotating Speed | 0-10 RPM | ||

| Thermocouple | K Type x 3 pcs | ||

| Tube Function | Rotating and tilt function. | ||

| Max. Power | 12 KW | ||

| Working Voltage | AC 380V 3 phases, 50Hz | ||

| Temperature Control | 3 sets PID automatic control via SCR power control | ||

| Heating curves | 30 steps programmable | ||

| Chamber material | Alumina Fiber | ||

| Release Relief Valve | Relief automatically at 0.02Mpa | ||

| Heating Ribbon and temp. Controller Up to 300C |

On outlet side tube | ||

| Mechnical Pressure Gauge in inlet Measuring range: -0.1 to 0.15Mpa |

On inlet side tube | ||

| Warranty | One year limited warranty (Consumable parts such as heating elements are not covered by the warranty) | ||