Biomass pyrolysis furnace system

KJ-BPLE

KJ-BPLE Working temperature:

≤1100℃

Working temperature:

≤1100℃

Tube Material:

High purity quartz Tube

Tube Material:

High purity quartz Tube

Application:

KJ-BPLE mainly used for laboratory biomass pyrolysis experiments.

Application:

KJ-BPLE mainly used for laboratory biomass pyrolysis experiments.

Introduction

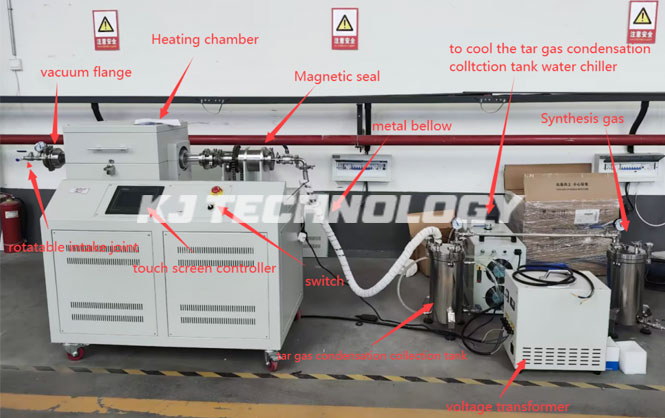

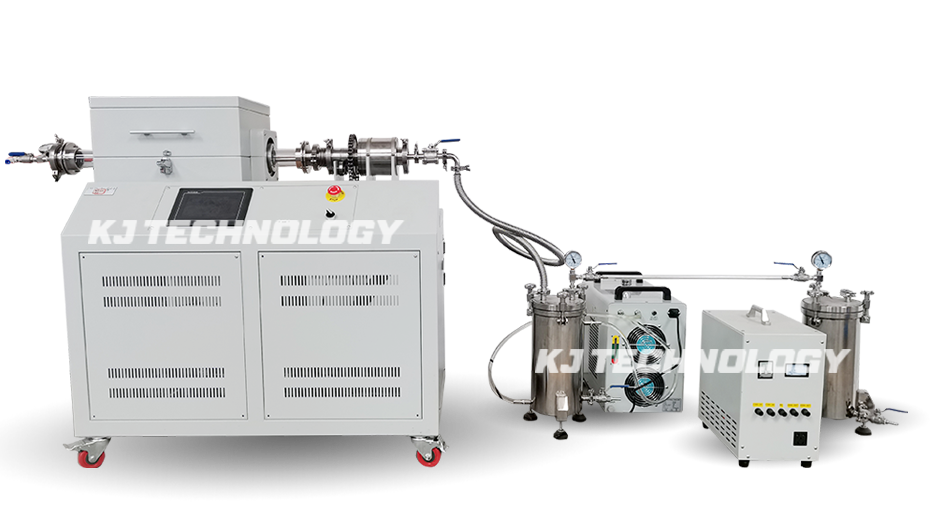

KJ-BPLE mainly used for laboratory biomass pyrolysis experiments. The whole set of equipment includes pyrolysis furnace, tar gas condensation collection tank, synthesis gas collection tank, There is a gas outlet in the gas collection tank, which is convenient for connecting to a gas analyzer for gas composition analysis experiments of synthesis gas.

| Technical Parameter | |||

| Model | KJ-BPLE | ||

| Display | LCD touch screen | ||

| Working Temperature | ≤1100℃ | ||

| Heating Rate | 0~20℃/min ,≤10℃/min recommended | ||

| Heating Zone | Big belly quartz tube OD100 mm in the middle and two ends are OD60mm |

||

| Tube Material | High purity quartz Tube | ||

| Heating Element | Resistance Wire With Mo | ||

| Tube Rotating Speed | 0-10 RPM | ||

| Furnace Tilt Angle | 0~30 degree | ||

| Thermocouple | K type | ||

| Temperature Control | PID automatic control via SCR power control | ||

| Heating curves | 16 temperature curves can be set,each temperature curve can be automatically set with 30 steps programmable. | ||

| Chamber material | Alumina Fiber | ||

| Rotatable intake joint | Easy access to carrier gas | ||

| Metal bellows connecting pyrolysis furnace and condensate tank | Wrapped by heating tape to prevent syngas from cooling before entering the condensate tank. | ||

| Tar gas collection | Tar gas condensation collection tank with Water chiller to cool the gas |

||

| Synthesis gas collection tank | Collect synthesis gas for sampling analysis | ||

| Max.power | 4KW | ||

| Warranty | One year limited warranty (Consumable parts such as quartz tube are not covered by the warranty) | ||