Biomass semi-gasification burner system

Long Life /Automatic/ Safe&Stable /Eco-Friendly

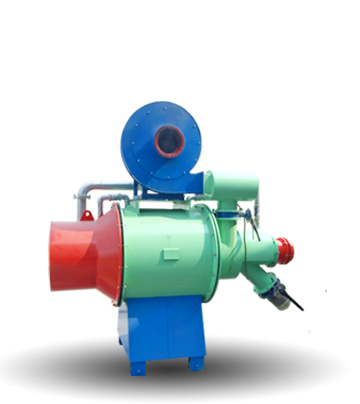

HQ-LKPellet Burner

HQ-LKPellet Burner

ONLINE CHAT

ONLINE CHAT MESSAGE

MESSAGE HQ-LMWood Chip Burner

HQ-LMWood Chip Burner

ONLINE CHAT

ONLINE CHAT MESSAGE

MESSAGE

HQ-LJMultifunctional Burner

HQ-LJMultifunctional Burner

ONLINE CHAT

ONLINE CHAT MESSAGE

MESSAGE

HQ-WMWood Powder Burner

HQ-WMWood Powder Burner

ONLINE CHAT

ONLINE CHAT MESSAGE

MESSAGETechnical Parameters

| Technical Parameter | |||||||

| Pellet Burner | |||||||

| Equipment model | Equipment power (kw) | Equipment size (L*W*H) (mm) | Nozzle diameter and center height (mm) | Biomass consump tion (kg/h) | Heat value (kcal/h) | Reference weight (T) | Matched boiler capacity (T) |

| HQ-LK0.5T | 4.32 | 1900*900*1800 | 500*960 | 70 | 300,000 | 1 | 0.5 |

| HQ-LK1.0T | 4.32 | 1950*1310*2290 | 500*960 | 155 | 600,000 | 1.5 | 1 |

| HQ-LK2.0T | 8.95 | 2350*1700*2700 | 600*1160 | 310 | 1,200,000 | 2.5 | 2 |

| HQ-LK3.0T | 8.95 | 2500*1250*2800 | 600*1160 | 460 | 1,800,000 | 3 | 3 |

| HQ-LK4.0T | 12.95 | 2700*1950*2850 | 700*1260 | 600 | 2,400,000 | 3.5 | 4 |

| HQ-LK6.0T | 14.7 | 3100*2100*3100 | 800*1360 | 1000 | 3,600,000 | 5 | 6 |

| HQ-LK8.0T | 19 | 3150*2100*3050 | 900*1450 | 1200 | 4,800,000 | 7.2 | 8 |

| HQ-LK10T | 12.6 | 3250*2600*3150 | 900*1450 | 1500 | 6,000,000 | 9.5 | 10 |

| HQ-LK12T | 29.2 | 3500*2350*3250 | 1000*1450 | 1800 | 7,200,000 | 11 | 12 |

| HQ-LK16T | 43 | 3650*2600*3350 | 1200*1550 | 2400 | 9,600,000 | 14 | 16 |

| HQ-LK18T | 43 | 3650*2350*3350 | 1200*1550 | 2700 | 10,800,000 | 15.5 | 18 |

| HQ-LK20T | 43 | 3750*2450*3350 | 1200*1550 | 3000 | 12,000,000 | 18.5 | 20 |

| Note: 1、Suitable for size 6-10MM wood pellet, moisture: <15% 2、If technical parameters change, no further notice! |

|||||||

| Technical Parameter | |||||||||

| Multifunctional Burner | |||||||||

| Equipment model | Equipment power (kw) | Screw feeder(mm) | Fuel bin size(φ * h)mm | Burner size(l * w * h)mm | Muzzle diameter and center height(mm) | Sawdust consumption (kg/h) | Heating value (kcal/h) | reference weight(T) | Corresponding boiler model(T) |

| HQ-LJ0.5T | 16.66 | 219 | 1200*2200 | 1600*850*1600 | 480*1026 | 70 | 300,000 | 3.2 | 0.5 |

| HQ-LJ1.0T | 20.09 | 219 | 1500*3700 | 1800*1150*2000 | 630*1220 | 155 | 600,000 | 6.2 | 1 |

| HQ-LJ2.0T | 20.09 | 219 | 1500*3700 | 2000*1350*2000 | 630*1220 | 310 | 1,200,000 | 7.6 | 2 |

| HQ-LJ4.0T | 29.29 | 219 | 1500*3700 | 2200*1450*2300 | 700*1450 | 600 | 2,400,000 | 8.2 | 4 |

| HQ-LJ6.0T | 38.04 | 219 | 1500*3700 | 2900*1650*2350 | 700*1450 | 1000 | 3,600,000 | 8.8 | 6 |

| HQ-LJ8.0T | 52.54 | 219 | 1500*3700 | 2800*1950*2400 | 800*1450 | 1200 | 4,800,000 | 10.5 | 8 |

| HQ-LJ10T | 52.54 | 219 | 1500*3700 | 2900*2050*2400 | 800*1450 | 1500 | 6,000,000 | 11.5 | 10 |

| HQ-LJ12T | 66.04 | 219 | 2600*6000 | 3100*2150*2500 | 900*1600 | 1800 | 7,200,000 | 14 | 12 |

| HQ-LJ16T | 82.54 | 219 | 2600*6000 | 3500*2350*2600 | 1000*1650 | 2400 | 9,600,000 | 15 | 16 |

| HQ-LJ20T | 82.54 | 219 | 2600*6000 | 3600*2550*2600 | 1000*1650 | 3000 | 12,000,000 | 18.6 | 20 |

| Note: 1、Suitable for size 6-10MM wood pellet,

moisture:

<15% 2、If technical parameters change, no further notice! |

|||||||||

| Technical Parameter | |||||||

| Wood Chip Burner | |||||||

| Equipment model | Equipment power (kw) | Equipment size (L*W*H) (mm) | Nozzle diameter and center height (mm) | Biomass consump tion (kg/h) | Heat value (kcal/h) | Reference weight (T) | Matched boiler (T) |

| HQ-LM0.5T | 3.62 | 1900*1250*1800 | 390*960 | 70 | 300,000 | 1 | 0.5 |

| HQ-LM1.0T | 4.32 | 1950*1380*2290 | 500*960 | 155 | 600,000 | 1.5 | 1 |

| HQ-LM2.0T | 8.95 | 2350*1850*2700 | 600*1160 | 310 | 1,200,000 | 2.5 | 2 |

| HQ-LM3.0T | 8.95 | 2500*1850*2800 | 600*1160 | 460 | 1,800,000 | 3 | 3 |

| HQ-LM4.0T | 12.95 | 2700*2025*2850 | 700*1260 | 600 | 2,400,000 | 3.5 | 4 |

| HQ-LM5.0T | 12.95 | 2800*2030*3000 | 700*1260 | 750 | 3,000,000 | 4.3 | 5 |

| HQ-LM6.0T | 14.7 | 3100*2300*3100 | 800*1360 | 1000 | 3,600,000 | 5 | 6 |

| HQ-LM7.0T | 14.7 | 3100*2400*3100 | 800*1360 | 1100 | 4,200,000 | 6 | 7 |

| HQ-LM8.0T | 19 | 3250*2780*3150 | 900*1450 | 1200 | 4,800,000 | 7.2 | 8 |

| HQ-LM9.0T | 19 | 3250*2900*3150 | 900*1450 | 1350 | 5,400,000 | 8.6 | 9 |

| HQ-LM10T | 22.5 | 3250*2950*3150 | 900*1450 | 1500 | 6,000,000 | 9.5 | 10 |

| Note: 1、Suitable for size 6-10MM wood pellet,

moisture:

<15% 2、If technical parameters change, no further notice! |

|||||||

| Technical Parameter | |||||||

| Wood Powder Burner | |||||||

| Equipment model | Equipment power(kw) | Fuel bin size(φ * h)mm | Burner size(L * W * H)(mm) | Nozzle diameter and center height(mm) | Wood powder consumption(kg/h) | Heating value(kcal/h) | Reference weight(T) |

| HQ-W0.5T | 7.07 | Type V 2500*1600*1500 | 1980*900*2100 | 500*950 | 70 | 300,000 | 3.2 |

| HQ-W1.0T | 7.07 | Type V 2500*1600*1500 | 1900*950*2100 | 500*950 | 155 | 600,000 | 6.2 |

| HQ-W2.0T | 9.75 | Type V 2500*1700*1600 | 2060*1050*2330 | 600*1040 | 310 | 1,200,000 | 7.6 |

| HQ-W3.0T | 9.75 | Type V 2500*1700*1600 | 2160*1050*2430 | 600*1040 | 460 | 1,800,000 | 7.8 |

| HQ-W4.0T | 18.75 | Type V 2500*1800*1700 | 2150*1120*2630 | 860*1160 | 600 | 2,400,000 | 8.2 |

| HQ-W6.0T | 18.75 | Type V 2500*1800*1700 | 2150*1320*2630 | 860*1160 | 1000 | 3,600,000 | 8.8 |

| HQ-W8.0T | 31 | Ø2600*6000 | 3050*1600*3170 | 1200*1320 | 1200 | 4,800,000 | 10.5 |

| HQ-W10T | 31 | Ø2600*6000 | 3150*1800*3170 | 1200*1320 | 1500 | 6,000,000 | 11.5 |

| HQ-W12T | 51.54 | Ø2600*6000 | 3250*1800*3250 | 1300*1450 | 1800 | 7,200,000 | 12.8 |

| HQ-W14T | 51.54 | Ø2600*6000 | 3350*1800*3250 | 1300*1450 | 2100 | 8,400,000 | 13 |

| HQ-W16T | 68.04 | Ø2600*6000 | 3500*1800*3300 | 1400*1600 | 2400 | 9,600,000 | 15.2 |

| HQ-W20T | 68.04 | Ø2600*6000 | 3500*1950*3300 | 1400*1600 | 3000 | 12,000,000 | 18 |

| Note: 1、Suitable for size 6-10MM wood pellet,

moisture:

<15% 2、If technical parameters change, no further notice! |

|||||||

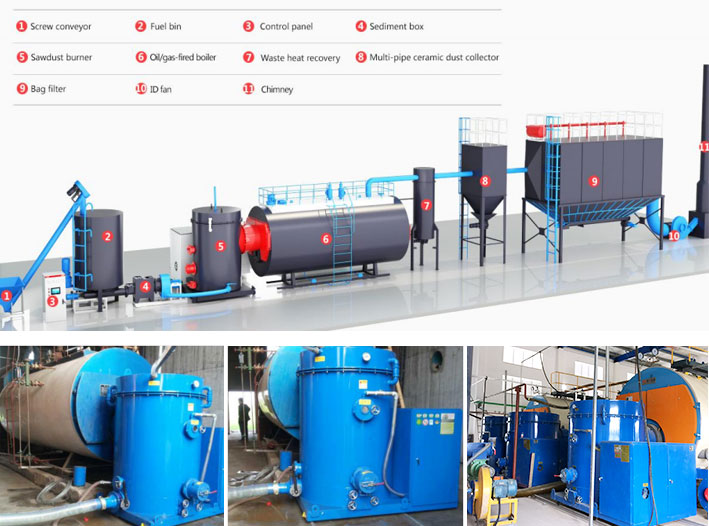

Basic Configuration Of Biomass Semi-gasification Burner

Basic configuration of pellet burner

Basic configuration of pellet burner Customize Your Basic Configuration

Customize Your Basic Configuration

Basic configuration of Multifunctional burner

Basic configuration of Multifunctional burner Customize Your Basic Configuration

Customize Your Basic Configuration

Basic configuration of wood chip burner

Basic configuration of wood chip burner Customize Your Basic Configuration

Customize Your Basic Configuration

Basic configuration of wood powder burner

Basic configuration of wood powder burner Customize Your Basic Configuration

Customize Your Basic Configuration

Steam boiler

Asphalt heat equipment

Drying equipment

Spray drying line

Coal-fired boiler

Aluminum melting furnace

Incinerator

Forging heating

Big Capacity

Big CapacityKJ Technology biomass semi-gasification sawdust burner can generate 18 million Kcal/h of heat, matched 30 tons of boiler. Specifically for the industrial sector, 24-hour continuous operation can be achieved.Our company has a complete range of equipment with a heat capacity of 300,000- 18,000,000 Kcal/h, matched boiler of 0.5 to 30 tons.

Intelligent

Intelligent1. Safe automatic feeding, automatic alarm switching function.

2. Large-medium-low fire can be automatically switched by operating conditions.

3. One-button to start, safe automatic ignition.

4. Manual-automatic switching, can adapt different operating conditions.

Long Life

Long Life1. Professional refractory material pouring technology, anchor nail reinforcement, and reasonable expansion joint technology.

2. The furnace top is protected by 4 layers of American refractory materials. The muzzle is made of imported high-aluminum material, which is resistant to erosion and high temperature.

3. The outer water jacket protects and reduces the furnace surface temperature.

More Efficient

More Efficient1. The main body adopts three layers of insulation to reduce heat loss.

2. High-temperature cracking and multi-stage vortex oxygenation ensure complete combustion of raw materials.

3. Suspended fluidized combustion increases the contact area with oxygen, making the fuel burn fully and evenly, and the overall thermal efficiency is as high as over 85%.

Safer

Safer1.The furnace front and furnace back system can realize interconnection interlocking, explosion-proof combustion and anti-tempering.

2.Mi cro-negative pres sure system operation, simple operation on duty.

3.The furnace body is equipped with a thermometer, and the temperature of the furnace body can be observed at any time to avoid high temperature damage to the furnace body and the risk of burns to the operator.

Greener

Greener1.Biomass fuel has low cost, automatic control saved labor cost, and high-tech design with more efficiency, comprehensive energy-saving effect is obvious.

2.Meet environmental standards, biomass fuel emissions are almost zero pollution, sulfur dioxide and nitrogen oxides are much lower than the national emission standards.

3.The cos t of recovery is fast, tens of thousands of dollars invested, and millions of dollors are saved per year.

Waste to wealth, green and environmental.We are on the way!

6T Coal-fired Boiler ReformBoiler Type :Coal-fired boeiler

Boiler Capacity : 6T

Steam Pressure : 10k

Installatlon Location : Changchun

Installatlon Tlme : 2017

Construction Time : 30 days ( With equipment produetion )

Daily Working Hours:16 hours Get Case Information

Get Case Information

Connect with Gas BoilerBoiler Type: steam boiler

Boiler Capacity: 4 tons

Steam Pressure: 8 kg

Installation Location: Hebei Xingtai

Installation Time: 2014

Project Construction Time: 30 days

(including equipment production)

Daily Working Time: 20 hours

Natural Gas Consumption: 270m3/h

Natural Gas Price: 3.2 RMB/m3

Sawdust Consumption: 600kg/h

Sawdust Price: 0.5 RMB/kg

Cost Savings: 3.38 million RMB/year (300days operation) Get Case Information

Get Case Information

Connect with DryerSawdust Burner Model: HQ-LJ4.0

Installation Location: Portugal

Installation Time: 2014

Dryer Type: drum dryer

Dryer Model: φ2.4*22 m

Drying Materials: Sawdust

Moisture Requirements: 40% of initial

moisture, final: 12%

Dryer Output: about 4 tons

Sawdust Consumption: about 600kg/h

Sawdust Price: 0.8 RMB/kg

Annual Cost Savings: 4.03 million/year

(300 days operation) Get Case Information

Get Case Information

Do you still have a question regarding our services?

Do you still have a question regarding our services?