Biomass gasifier system

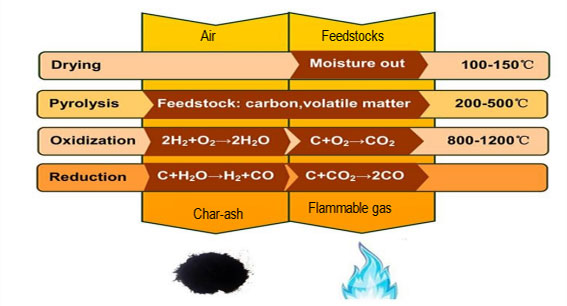

Biomass gasification refers to the thermochemical process of converting biomass fuels into flammable gases. In this process, water vapor, free oxygen, or bound oxygen reacts with the carbon in the fuel to form a combustible gas. Biomass gasification process is more complex and the gasification reaction conditions are also different. However, all the gasification reaction processes basically include the processes of biomass drying, pyrolysis, oxidation and reduction.

Swedish Modern Biomass Power Plant

Swedish Modern Biomass Power Plant

American Biomass Power Plant

American Biomass Power Plant

In developed countries, biomass tilization as an energy source adopt high-input and high-output methods to build large scale biomass energy conversion projects and transform traditional biomass into modern energy use. At present, the biomass power industry has become the second largest renewable energy source after hydropower in the United States. The conversion of biomass into modern energy has accounted for 40%,16% and 10% of the basic energy consumption in the United States, Sweden and Austria respectively. Among the EU countries, biomass energy has accounted for 59.6% of all new and renewable energy sources (including hydropower) developed and uilized.

| Technical Parameters | ||||||||

| Gasifier Model and Output Parameters | ||||||||

| Category | Item | HQ-LX1500 | HQ-LX1800 | HQ-LX2000 | HQ-LX2200 | HQ-LX2400 | HQ-LX2600 | HQ-LX3000 |

| Fuel | Material consumption | 80-140kg | 160-280kg | 300-400kg | 500-600kg | 700-800kg | 900-1000kg | 1200-1500kg |

| Granularity | Wood chips:30-50mm ;Plant straw≤100mm | |||||||

| Moisture | <20% | |||||||

| Biomass gas | Theoretical output | 240-320m³ | 480-680m³ | 900-1200m³ | 1200-1400m³ | 1600-1800m³ | 2200-2600m³ | 2800-3200m³ |

| Mixed gas heating value | 1100-1300kcal/m3 | |||||||

| Performance | Gasification rate M3/kg | Woody:2-3 m3 Herbs:1-1.5m3 | ||||||

| By-products | Each ton of raw materials can produce charcoal 200-400kg、tar30kg、Wood vinegar250kg | |||||||

| Biomass Gas Composition | ||||||||

| Category | CO | H₂ | CH₄ | CO₂ | N₂ | O₂ | CmHn | H₂S |

| Content | 20-25% | 10-13% | 2-4% | 13% | 46% | 1% | 0.8 | 16.4mg/Nm³ |

Core technology

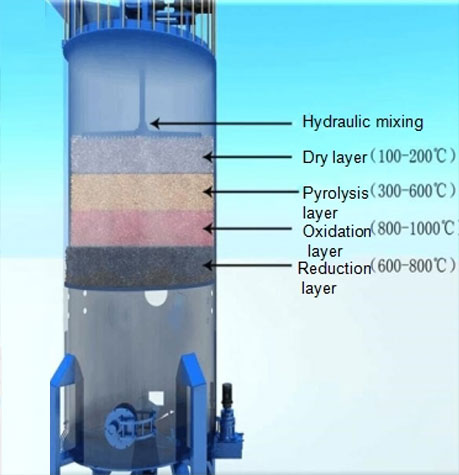

1 Drying layer:The uppermost layer of the gasifier is a drying zone. The material added from the top enters the drying zone directly. The material here exchanges heat with the hot gas produced in the following three reaction zones to evaporate the water in the raw material. The layer temperature is 100~ 300℃. The product of the dry layer is dried material and steam. The steam exits the gasifier with the heat generated in the following three reaction zones, and the dry material falls into the pyrolysis zone.

2.Pyrolysis layer: The bio-dry material runs down into the pyrolysis layer and heats the biomass at the same time. When the biomass is heated, pyrolysis occurs. Through the pyrolysis reaction, most of the volatiles in the biomass are separated from the solid and basically completed at 500- 600°C,leaving charcoal. The main products of the pyrolysis zone are carbon, hydrogen,steam, carbon monoxide, carbon dioxide, methane, tar and other hydrocarbons.

3.Oxidation layer:The pyrolyzed remaining charcoal reacts violently with air and releases a lot of heat. Since oxygen-limited combustion,the supply of oxygen is insufficient, and incomplete combustion reaction occurs at the same time, carbon monoxide is generated, and heat is also released. In the oxidation zone, the temperature can reach 1000 ℃. In the oxidation zone, all the combustion reactions are carried out and heat is released. This part of the reaction heat is the reduction reaction in the reduction zone, the cracking and drying of the materials, and provides the heat source. The hot gases (carbon monoxide and carbon dioxide) generated in the oxidation zone enter the reduction zone of the gasifier and the ash falls into the lower gray chamber.

4.Reduction layer: Oxygen is not present in the reduction zone. Carbon dioxide generated in the oxidation reaction undergoes a reduction reaction with carbon and water vapor to produce carbon monoxide (CO) and hydrogen (H2). Since the reduction reaction is an endothermic reaction, the temperature in the reduction zone also decreases accordingly, and is about 600-800°C. The main products of the reduction zone are carbon monoxide (CO), carbon dioxide (CO2) and hydrogen (H2). Gasification is actually always a combination of the dry cracking process of fuels. In the actual operation process, the above four areas have no clear boundaries and are infiltrated and staggered. Therefore, at the outlet of the gasifier, the composition of the produced gas is mainly carbon monoxide (CO), carbon dioxide (CO2), hydrogen (H2), methane (CH4), tar, and a small amount of other hydrocarbons, as well as water vapor and a small amount of ash.

Comprehensive application system of biomass gasifier

introduction raw material

raw material main energy

main energy application field

application field

introduction raw materials

raw materials main energy

main energy application field

application field

Waste to wealth, green and environmental.We are on the way!

Carbon Gas CogenerationVietnamese drying enterprises use rice husk raw material gasification gas as the heat source of the drying system. The rice husk charcoal produced is supplied to local steelmaking plants as a carburizing agent. The local rice husk gas is almost zero cost, saving customers about 700 million VND, or more than 2 million yuan, in fuel costs every year. Get Case Information

Get Case Information

Heat ConcentrationQingzhou University in Shandong Province uses biomass gasifiers to provide heat sources to assist in central heating of 140,000 square meters of campus. As a biomass new energy demonstration base project jointly built by the school and the local government. During the heating season, the revenue from the sale of gasified biomass carbon alone is about 600,000 yuan, and the comprehensive annual cost is about 3.7 million yuan less than that of traditional municipal heating. Get Case Information

Get Case Information

Carbon Fertilizer Co-productionHenan Sanli Straw Carbonization Processing Factory is entrusted with government subsidies to comprehensively process straw using biomass gasification mode. The straw char produced is deeply processed into various special ecological fertilizers for soil improvement and feed additives to develop ecological agriculture and create efficient Ecological and economic value. Get Case Information

Get Case Information

Do you still have a question regarding our services?

Do you still have a question regarding our services?